Revolutionizing Aluminum Processing: The Role of the Silicon Nitride Ceramic Degassing Rotor

The global aluminum industry faces constant pressure to improve quality and efficiency while reducing operational costs. A critical step in ensuring high-quality aluminum is degassing, the process of removing unwanted hydrogen gas and non-metallic inclusions from the molten metal. Traditional materials used in degassing rotors often suffer from short service life, high maintenance requirements, and contamination issues. This is where the Silicon Nitride Ceramic Degassing Rotor emerges as a transformative technology, fundamentally changing how molten aluminum is treated.

Superior Material Science: Why Silicon Nitride Excels

The core of the technology’s superiority lies in the material: silicon nitride (). Silicon nitride is a high-performance engineering ceramic renowned for its exceptional properties, making it an ideal material for the harsh, high-temperature environment of molten aluminum processing.

Key Material Advantages

- Excellent Thermal Shock Resistance: Degassing rotors are subjected to rapid and significant temperature changes as they move in and out of the molten aluminum bath. Silicon nitride’s robust resistance to thermal shock prevents cracking and ensures a long, stable operational life.

- High Strength and Hardness: exhibits superior mechanical strength, allowing the Silicon Nitride Ceramic Degassing Rotor to operate effectively at high rotation speeds without deformation or failure, which is crucial for maximizing degassing efficiency.

- Non-Wetting Property: The material is non-wetting to molten aluminum and dross. This property significantly reduces the build-up of aluminum oxide and corundum on the rotor surface, minimizing maintenance time and maintaining optimal performance over longer periods.

- Chemical Inertness: Silicon nitride is chemically inert to the aggressive environment of the molten aluminum, preventing contamination of the metal—a critical factor for producing high-purity alloys used in aerospace and automotive industries.

Enhancing Degassing Efficiency and Quality

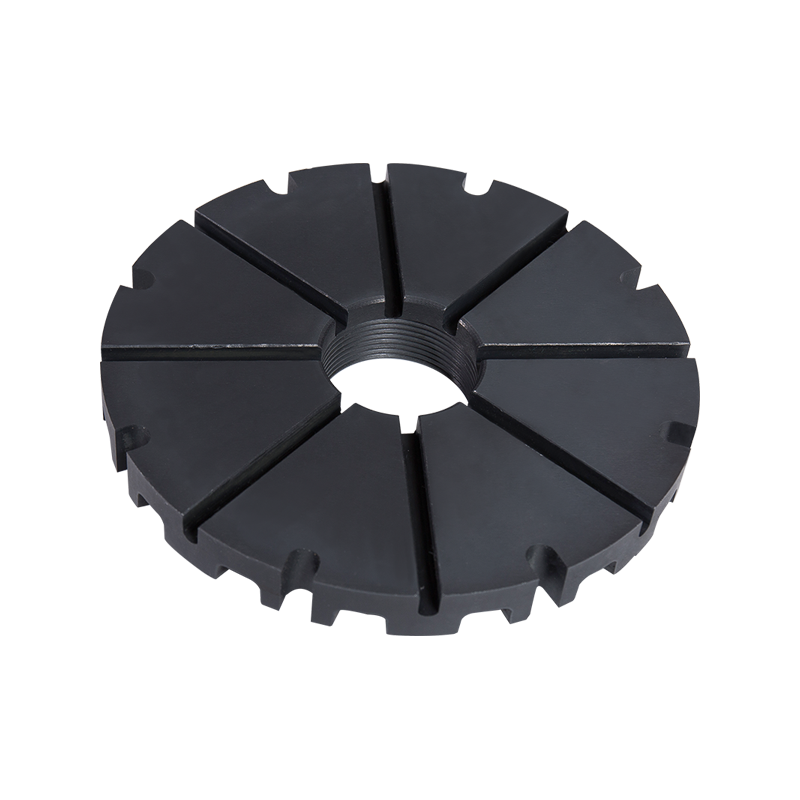

The physical design of the Silicon Nitride Ceramic Degassing Rotor complements its material advantages. The rotor is designed to inject an inert gas, typically argon or nitrogen, into the melt and shear the gas into extremely fine bubbles.

The Mechanism of Action

The fine, numerous gas bubbles create a vast surface area as they rise through the molten aluminum. Hydrogen dissolved in the aluminum diffuses into these bubbles, and non-metallic inclusions are captured. As the bubbles reach the surface, they carry the impurities away, significantly reducing the concentration of hydrogen and inclusions. The high-speed rotation and sophisticated geometry of the Silicon Nitride Ceramic Degassing Rotor ensure highly efficient gas dispersion and circulation of the melt, leading to rapid and thorough purification.

By enabling cleaner aluminum, the use of a Silicon Nitride Ceramic Degassing Rotor results in final cast products with improved mechanical properties, better surface finish, and fewer internal defects like porosity, ultimately reducing scrap rates and increasing product yield.

Economic and Environmental Impact

The adoption of the Silicon Nitride Ceramic Degassing Rotor translates into significant economic and environmental benefits for aluminum smelters and foundries.

- Lower Operating Costs: The extended lifespan and reduced dross accumulation offered by the Silicon Nitride Ceramic Degassing Rotor decrease the frequency of rotor replacement and cleaning, leading to substantial savings on maintenance, labor, and downtime.

- Energy Efficiency: The non-wetting surface and structural integrity maintain high efficiency, ensuring the required level of degassing is achieved in less time or with less power consumption compared to less durable materials like graphite.

- Sustainability: By reducing maintenance waste and improving the quality of the final product, the technology contributes to a more sustainable and resource-efficient production cycle within the aluminum sector.

In conclusion, the Silicon Nitride Ceramic Degassing Rotor represents a paramount advancement in molten metal treatment technology. Its proven performance characteristics—rooted in the exceptional properties of silicon nitride—are essential for manufacturers striving for the highest quality aluminum and efficient, reliable production processes.

Contact Us for Quotes and Prices!

Just let us know what you want, and we will get in touch with you as soon as possible!

English

English 简体中文

简体中文