The Unsung Hero of High-Quality Metal: Silicon Nitride Degassing Rotor

The Purity Problem in Metal Casting

Imagine crafting a perfect object—a lightweight car part, a flawless aerospace component, or even a critical piece of medical equipment. If you start with a faulty material, the final product is destined to fail. This is the challenge in metal casting, particularly with materials like aluminum.

Aluminum, the miracle metal known for its strength-to-weight ratio, presents a major metallurgical problem: it loves to absorb hydrogen when molten. This happens easily—from moisture in the air, wet tools, or even surface oxides. Hydrogen is highly soluble in liquid aluminum, but as the metal cools and solidifies, the hydrogen is violently expelled, forming tiny pockets or voids called porosity.

Why Porosity is the Enemy

Porosity is the archenemy of metal quality. These microscopic gas bubbles severely compromise the metal’s performance:

- Weakened Structure: Porosity reduces the overall tensile strength and fatigue life of the casting, making the final part susceptible to cracks and failure.

- Leakage: For parts designed to hold pressure (like engine blocks or pumps), porosity creates pathways for fluid leaks.

- Poor Surface Finish: When the surface is machined, these voids show up as tiny pinholes, ruining the aesthetic and integrity of the product.

To create high-integrity, defect-free castings, this dissolved hydrogen must be removed, a process known as degassing.

The Rotary Degassing Solution

The most effective and widely adopted method for industrial-scale purification of molten metal is rotary degassing. This ingenious process works on the simple principle of gas exchange and flotation.

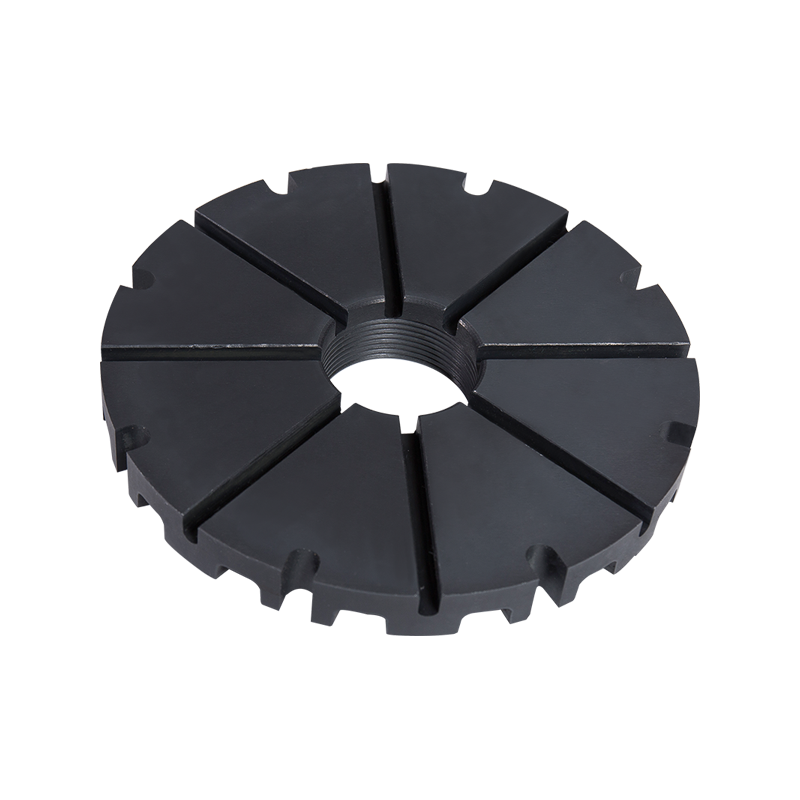

The main components of a rotary degassing system are a shaft and a specially designed rotor, which is lowered into the molten metal. An inert gas, typically argon or nitrogen, is pumped down the shaft and released through the rotor.

The rotor’s job is two-fold:

- Shear the Gas: The rotation of the rotor violently breaks the large streams of inert gas into an enormous number of tiny, finely dispersed bubbles.

- Mix the Melt: The spinning action circulates the bubbles uniformly throughout the entire molten bath.

As these tiny inert gas bubbles rise through the liquid aluminum, the dissolved hydrogen atoms diffuse out of the molten metal and into the bubbles, driven by the difference in partial pressure. The bubbles, now carrying the hydrogen, as well as non-metallic impurities (known as inclusions or dross) that stick to their surfaces, float to the top of the melt where they are skimmed off. The smaller and more numerous the bubbles, the greater the total surface area for hydrogen absorption, leading to a faster and more efficient purification process.

The Power of the Silicon Nitride Degassing Rotor

This is where the star of our story, the Silicon Nitride Degassing Rotor, steps in. Operating a rotor in molten aluminum—which can be up to () or higher—is one of the most demanding jobs in a foundry. The rotor is subjected to extreme conditions:

- Thermal Shock: Rapid changes in temperature when moved in and out of the melt.

- Chemical Attack: Exposure to reactive molten metals and fluxes.

- Mechanical Erosion: Constant abrasion from the flow of molten metal and non-metallic inclusions.

Early rotors made of materials like graphite often suffered rapid wear, losing their effectiveness quickly and contaminating the melt with carbon particles.

Silicon Nitride: A Material Marvel

Silicon Nitride () is a high-performance advanced ceramic that has revolutionized the degassing process. Its material properties make it the perfect match for this harsh environment:

- Exceptional Hardness: Silicon nitride is incredibly hard, giving it outstanding resistance to erosion and abrasion. This means the rotor maintains its precise geometric shape longer, ensuring consistently small, highly-efficient bubbles throughout its service life.

- Superior Thermal Shock Resistance: It can handle the massive temperature swings of the casting process without cracking or failing, leading to longer service life and less downtime.

- Chemical Inertness: Unlike graphite, silicon nitride is chemically inert and does not react with the molten aluminum, preventing contamination and maintaining the melt’s purity.

By using a Silicon Nitride Degassing Rotor, foundries can achieve a much higher quality of aluminum casting with lower hydrogen content, reduced inclusions, and ultimately, a more reliable and cost-effective production process. It is a critical component—a tiny, spinning piece of advanced engineering—that makes high-performance metal casting possible.

Contact Us for Quotes and Prices!

Just let us know what you want, and we will get in touch with you as soon as possible!

English

English 简体中文

简体中文