Why Silicon Nitride is the New Backbone of High-Performance Engineering

Exceptional Material Properties of Silicon Nitride

Silicon Nitride is a high-performance technical ceramic characterized by an extraordinary combination of physical and thermal properties. Unlike traditional metals, it maintains high mechanical strength and fracture toughness even at extreme temperatures exceeding 1000°C. Its covalent bonding structure results in a material that is significantly lighter than steel—roughly 40% of the density—while offering superior hardness and wear resistance. This makes it an ideal candidate for environments where weight reduction and durability are critical factors.

One of the standout features of Silicon Nitride is its remarkable thermal shock resistance. Due to its low coefficient of thermal expansion and high thermal conductivity, it can withstand rapid temperature fluctuations without cracking or degrading. This resilience allows the material to perform reliably in demanding propulsion systems, industrial furnaces, and chemical processing units where other materials would succumb to thermal fatigue.

Key Applications in Modern Industry

Aerospace and Automotive Engineering

In the aerospace sector, Silicon Nitride is used for turbine blades, spark plugs, and engine valves. Its ability to operate at higher temperatures than nickel-based superalloys allows for improved fuel efficiency and reduced emissions. In the automotive world, the material is frequently found in turbocharger rotors and glow plugs, where its low inertia and high heat tolerance provide faster response times and longer component lifespans.

Precision Bearings and Mechanical Seals

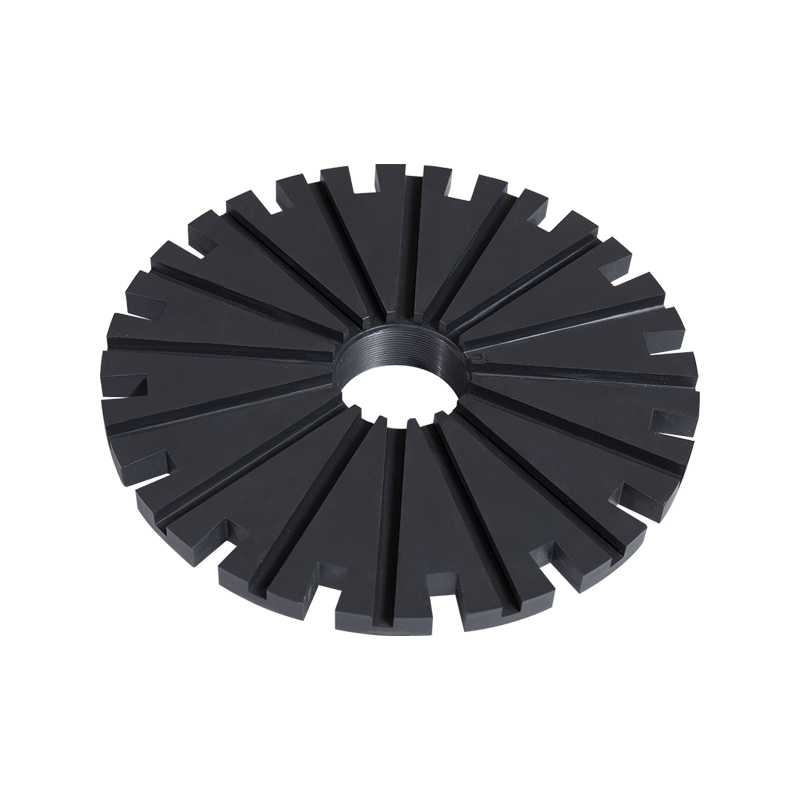

Silicon Nitride is the gold standard for "hybrid" bearings, which use ceramic balls with steel races. These bearings are preferred in high-speed applications, such as machine tool spindles and wind turbines, because the ceramic balls do not weld to the steel under extreme friction. Additionally, their non-conductive nature prevents electrical arcing, which is a common cause of bearing failure in electric motors and generators.

Comparative Performance: Silicon Nitride vs. Other Engineering Ceramics

To understand why Silicon Nitride is chosen over other advanced ceramics like Alumina or Zirconia, it is helpful to look at its specific performance metrics. The following table highlights the comparative strengths of Silicon Nitride in industrial contexts.

| Property | Silicon Nitride | Alumina (99%) | Zirconia (Y-PSZ) |

| Density | 3.2 | 3.9 | 6.0 |

| Thermal Shock Resistance | Excellent | Moderate | Fair |

| Fracture Toughness | High | Low | Very High |

| Hardness (HV) | 1500 - 1800 | 1600 - 2000 | 1200 - 1300 |

Manufacturing and Processing Varieties

The performance of Silicon Nitride is heavily influenced by the method used to manufacture it. Engineers select the processing route based on the complexity of the part and the required mechanical properties:

- Reaction Bonded Silicon Nitride (RBSN): Created by nitriding a silicon powder compact; it offers excellent dimensional stability but lower strength due to inherent porosity.

- Hot Pressed Silicon Nitride (HPSN): Produced by applying heat and pressure simultaneously; it results in a nearly 100% dense material with the highest possible strength.

- Sintered Silicon Nitride (SSN): The most common commercial variety, allowing for complex shapes through pressureless sintering while maintaining excellent all-around properties.

- Gas Pressure Sintered Silicon Nitride (GPSN): Uses high-pressure nitrogen gas to minimize decomposition, resulting in high density and optimized thermal properties.

Future Outlook in Electronics and Medical Tech

The utility of Silicon Nitride is expanding beyond heavy machinery into the realms of microelectronics and medicine. In the semiconductor industry, it serves as a vital dielectric layer and passivation film, providing an effective barrier against water and ionic impurities. Its biocompatibility has also led to its use in spinal fusion implants, where its surface chemistry promotes bone growth while its anti-microbial properties reduce the risk of infection compared to traditional titanium or PEEK implants.

Contact Us for Quotes and Prices!

Just let us know what you want, and we will get in touch with you as soon as possible!

English

English 简体中文

简体中文